Airborne

The Project

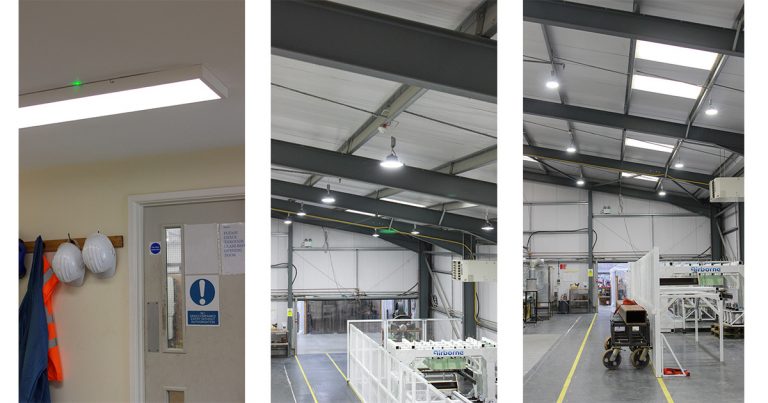

Airborne are a leader in the technology of advanced composites, with facilities in the Netherlands and in the UK. The business and composite manufacturing base in Berkshire, UK wanted to update their outdated existing lighting. By choosing Kosnic, Airborne UK could not only increase the light levels on the factory floor but could also save energy with the use of Kosnic’s highly efficient LED lighting.

The Solution

Initially Airborne UK just wanted to update the factory floor lighting as it was dim and out of date, which was not suitable for the highly detailed work that takes place on the factory floor. Once the requirements had been reviewed Kosnic created a cost of ownership to compare the existing fittings (5ft Twin VP fitting) against the 150W Echo high bay, once this was done the and the impressive savings were calculated it was decided to update the rest of their building with Kosnic LED lighting and then the installation began.

“We are very happy with the new lighting and professional service.”

– Joe Summers, Commercial Director at Airborne

The Result

With the full refit of Kosnic LED lighting the UK Airborne base now had improved light levels across the whole of the factory and offices as well as an impressive energy saving of over £58,000 over the lifetime of the LED.

Energy Saving - Fast Facts

Overall annual KWh reduction: 24,820 KWh

Overall annual CO2 (KG) reduction: 13,204 CO2

Overall annual spend (£) reduction: £4,470.23 (compared to traditional flourescent installation)

Payback Period: 10 months

£ Savings over life of LED: £58,282.00

Products used:

• 150W Echo High Bay

• 5ft Mira standard & emergency interior battens

• 5ft Milo interior batten with edge-lit LED panel with UEM

• 30W Twin bar panels